Minimizes restart times following breakdowns

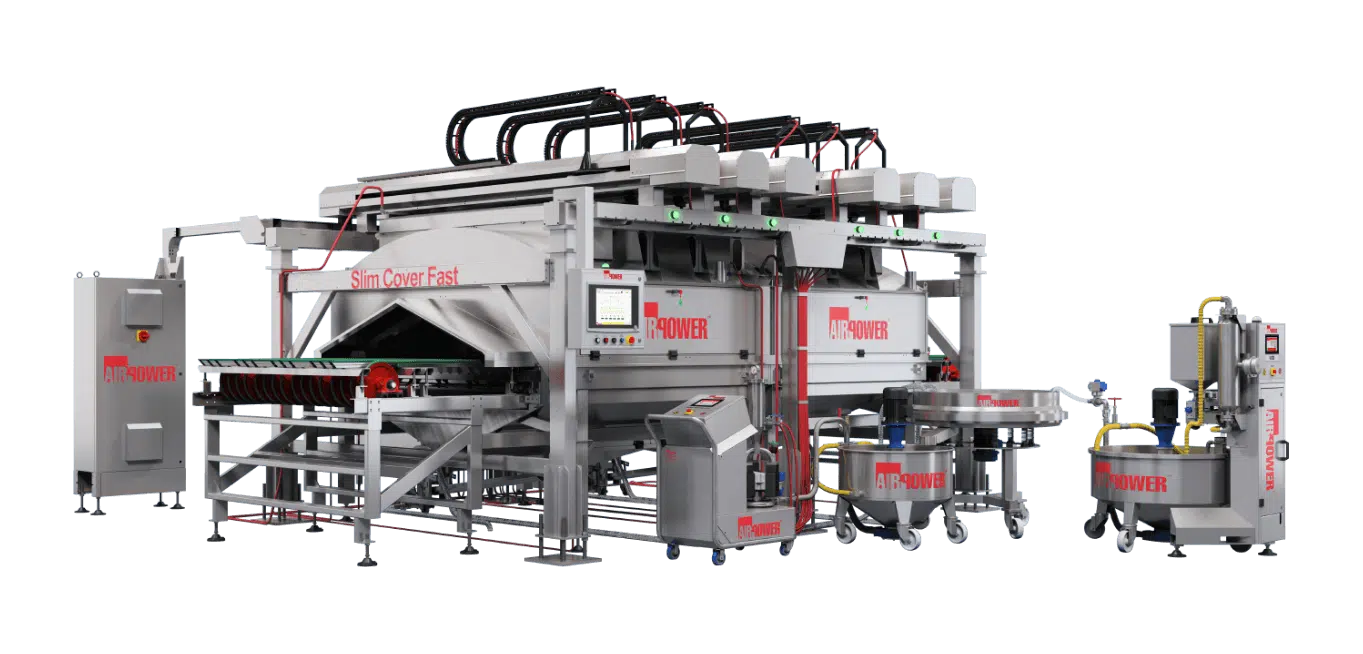

Slim Cover Fast

Application machine for large formats, Slim Cover Fast is a certainty in the airless application of large formats.

Description

Ceramic glazing machine for applications on large formats\slabs.

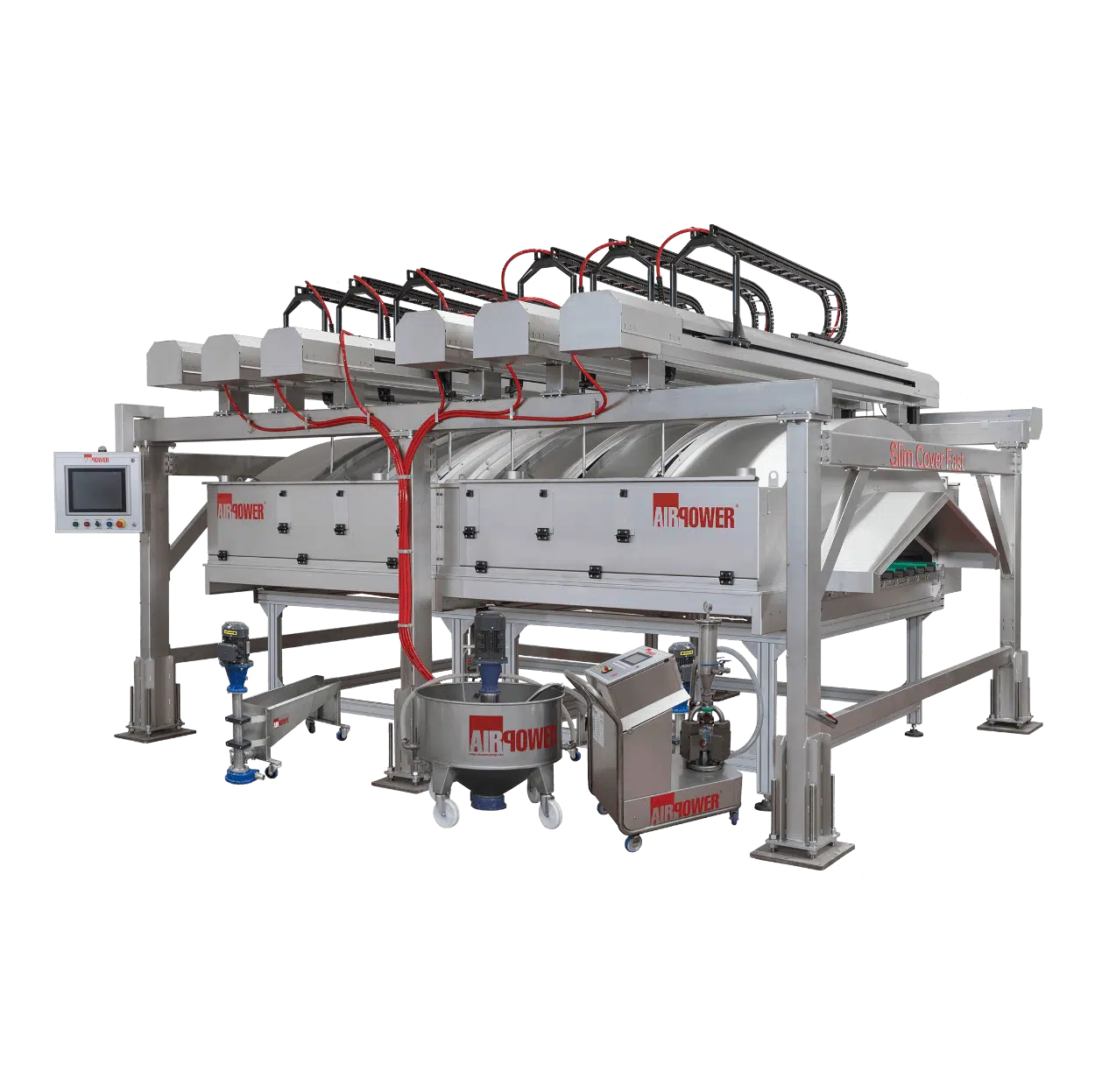

Available with 4 / 6 /8 / 10 upper translation axes with anti-vibration carbon fiber components.

The Slim Cover Fast series constitutes absolute excellence in the field of application machines for glazing large slabs. More precisely, the added value of this machine compared to other application machines consists of the following fundamental and distinctive features:

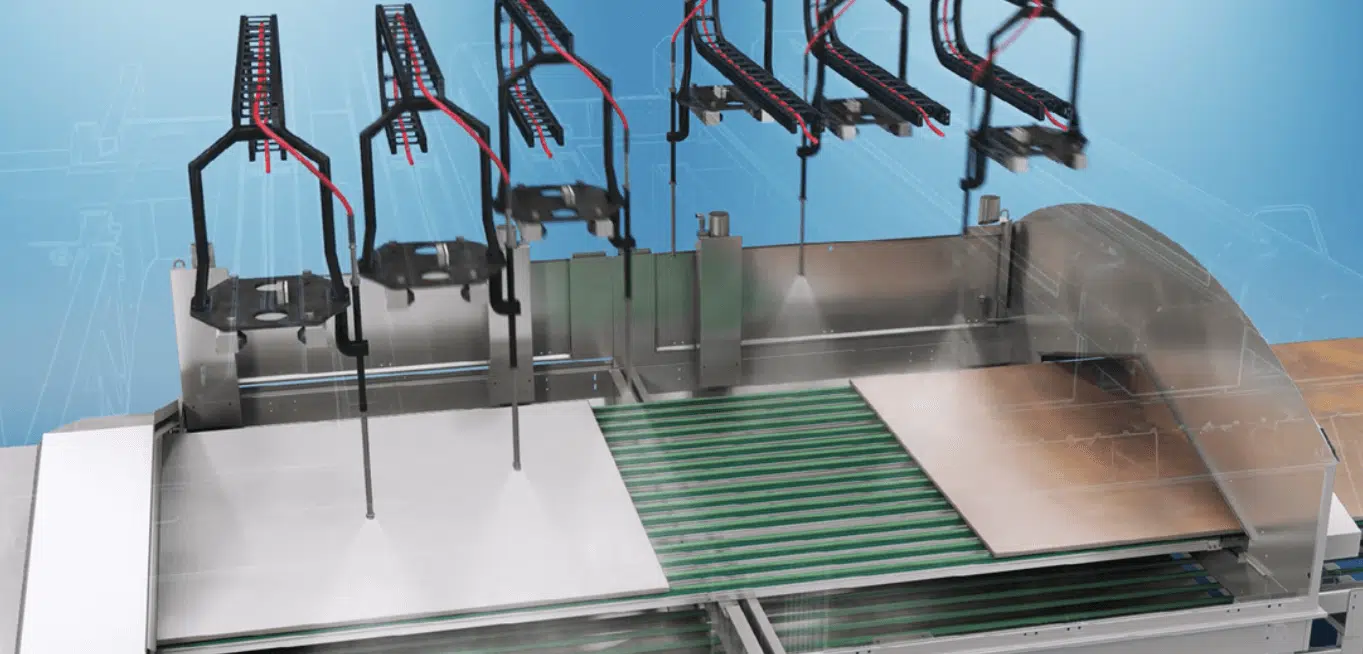

- Upper translatory axes and completely independent guns allow control of the desired application weight.

- The start of the axes is delayed until the tile is in position to be glazed

- Possibility of creating multiple trajectories of glaze on the surface of the tile with millimeter precision, in order to avoid any rhombus effect: in this way application intersections are optimized with minimum line speed, obtaining considerable energy savings.

- Possibility of crossing the axes during the processing phase, so it is possible to apply large formats or slabs at high speed, exponentially increasing the production yield. More precisely, we can apply from a minimum of 40 to a maximum of 1000g per m2.

- Automatic adjustment of the axes to obtain optimal performance.

- Remote control: Air Power 4.0 assistance team that allows immediate and total supervision of the machine and remote assistance as well as the possibility of starting the machine remotely. Minimizes restart times following sudden breakdowns.

Benefits

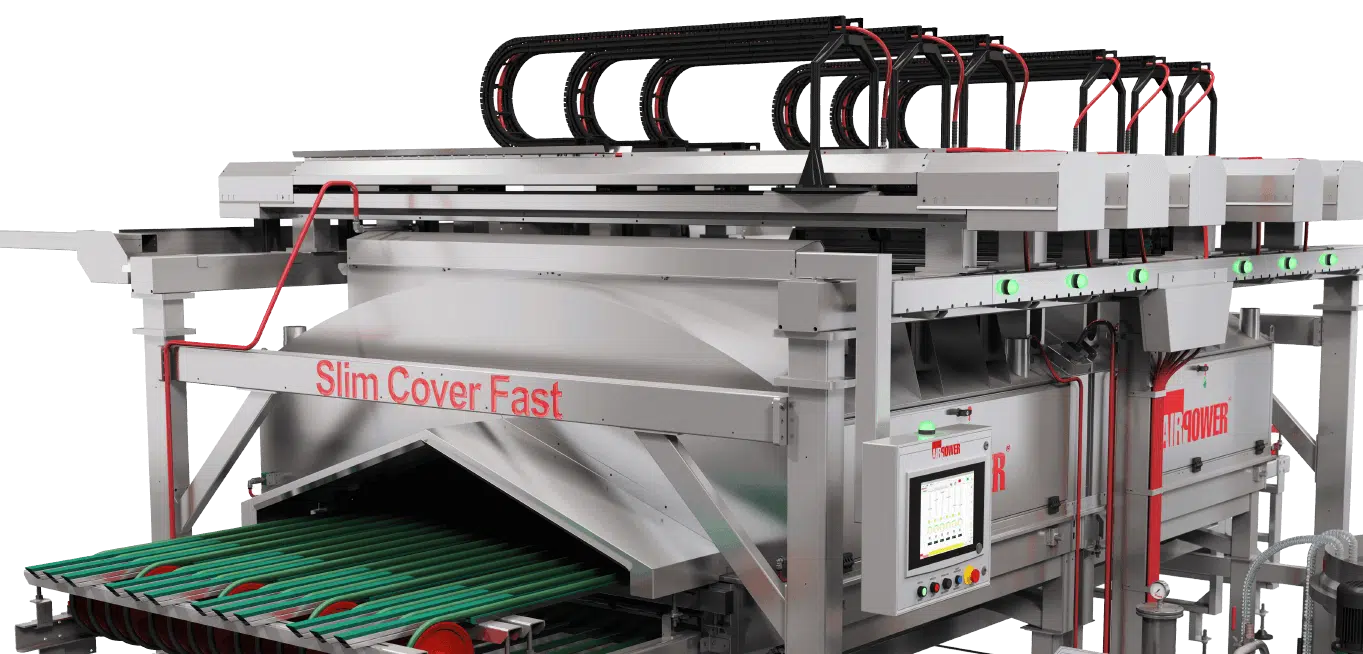

RAPID WASH SYSTEM, integrated on Slim Cover Fast: saving water, glaze and time, increasing productivity.

CONTROL FLUX SYSTEM, automatic flow control on the airless nozzle, integrated on Slim Cover Fast: eliminates flow instability for each nozzle, eliminates weight errors, checks wear and signals partial or total blockage, on each individual nozzle. Through predictive maintenance, i.e. the analysis of raw material consumption, it warns the operator in advance to replace the nozzles.

Considerable saving of suspended product

Multi-axis with independent translator axes

Scheduled departure

Upper axis with carbon fiber components

Machine learning, interconnection, real-time data: production control

Request Slim Cover Fast information

Contact us directly for more detailed information on the machinery or for quotation requests, thank you.