Operator intervention reduction

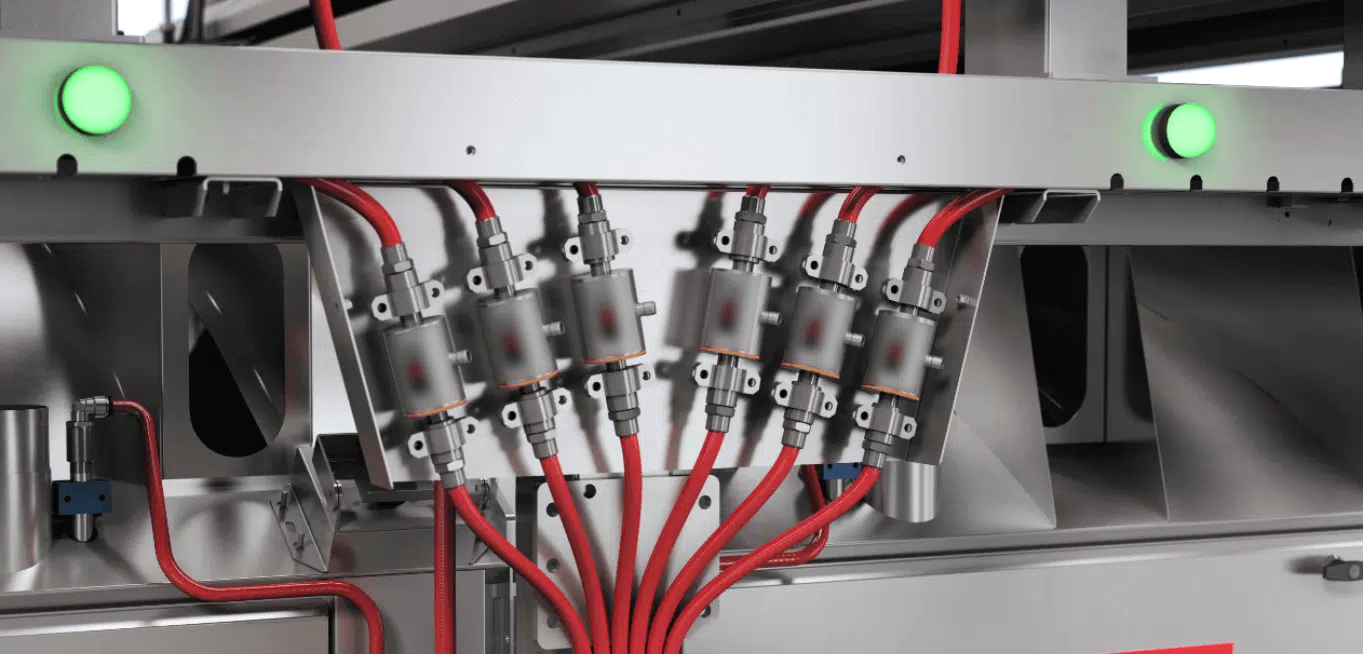

Control Flux

Through a continuous analysis of the engobe / glaze flow, Control Flux is able to recognize if the nozzle is partially or totally blocked.

Description

AUTOMATIC FLOW CONTROL ON SINGLE AIRLESS NOZZLE

Through a continuous analysis of the engobe / glaze flow through the nozzle, the machine is able to recognize if the nozzle is partially or totally blocked.

You can set 2 notification thresholds: warning and alarm.

The first threshold, warning, acts as a signal for the operator to obtain a new set of nozzles; the second, alarm, indicates that from that moment on we are producing with a lower quality due to the wear of the nozzle.

Available as a stand-alone accessory for airless cabins and single-axis Slim Covers or directly integrated on Slim Cover Fast.

Benefits

FLOW CONTROL

- Eliminates flow instability for single nozzle

- Eliminate the weight error

- Preset optimal usage thresholds

WEAR CHECK

- Checks wear and signals partial or total blockage on each individual nozzle

- Possibility of stopping the line and consequent elimination of production waste

PREVENTIVE MAINTENANCE

- Analysis of raw material consumption

- Prior notice to the operator for nozzle replacement (countdown 30/15/5 minutes before)

- Reduction to zero of the operator intervention time following a nozzle flow anomaly

Saving raw materials

Consistent production quality

2 thresholds: warning and alarm.

Request Control Flux information

Contact us directly for more detailed information on the machinery or for quotation requests, thank you.